Machining PE at Wefapress®: precision at every step

At Wefapress® we are experts in the processing of PE (polyethylene). Our process includes various techniques such as sawing, planing, drilling, milling and even welding to ensure that our products are made to our customers’ exact specifications. Each technique has its own specific parameters and requirements to achieve optimal results. From selecting the right cutting speed to choosing the right material for the tool, we pay attention to every detail to ensure the highest quality of our products.

Cutting speed: 40 – 70 m/min

Feed rate: 0.1 – 0.3 mm per revolution

Material: twist drills, pointed drills

Rake angle: 15 – 25 °

Clearance angle: Twist angle approx. 16°, A = 70 – 90°

Remark: Drilling machines or automatic drilling and milling machines, cooling can be done by compressed air. Pulsating drilling produces smoother hole walls and better chip evacuation, it also avoids overheating.

Cutting speed: 200 – 800 m/min

Feed rate: 0.1 – 0.3 mm per revolution

Material: Tungsten steel (18 % tungsten) or carbide

Rake angle: 15 – 25°

Clearance angle: 15 – 25°

Note: Normal milling machines, but especially high-speed routers. Milling tools with a low number of teeth provide good chip evacuation.

Cutting speed: 250 – 450 m/min

Feed rate: 0.1 – 0.3 mm per revolution

Material: tungsten steel (18 % tungsten) or hard metal

Rake angle: approx. 20

Clearance angle: 5 – 30 °

Note: Thickness planes or jointers as used in woodworking. Only sharp knives produce a smooth surface. There should be 4 knives on the shaft.a

Cutting speed: 3000 – 4000 m/min (for calculating the number of revolutions of your blade diameter)

Feed rate: 0.1 – 0.2 mm per tooth

Material: Carbide tipped blades

Remark: Circular saws, the higher the cutting speed, the cleaner the cut surface, height of cutting speed limited by frictional heat (can be influenced by cooling). Band saws (0.5 mm set), curved cutting etc. (feed 0.1 to 0.3 mm at approx. 1000 – 1500 m/min).

Our machinery: precision meets innovation

At Wefapress® we rely on the latest technologies to always provide our customers with the best solutions. Our machinery is the heart of our production and reflects our commitment to quality, precision and innovation.

We are proud to offer a wide range of manufacturing capabilities. From one-off production to small quantities and series production – we are able to produce plastic prefabricated parts at the highest level. Our manufacturing capabilities include sawing, milling, turning, profiling, drilling, welding and annealing.

5-axis machining

max. Length: 12.000 mm

max. Width: 2.500 mm

max. Height: 720 mm

4-axis machining

max. Length: 3,580 mm

max. Width: 920 mm

max. Height: 900 mm

max. Turning length: 3.000 mm

max. Diameter: 810 mm

max. Length: 10,000 mm (unwelded length, special length on request)

max. Width: 250 mm

max. Height: 180 mm

max. Width: 1.300 mm

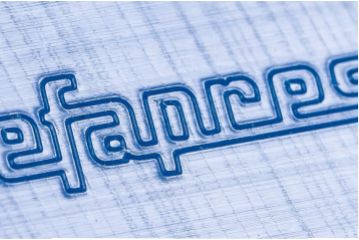

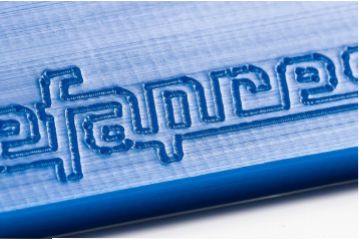

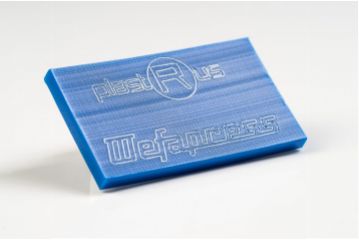

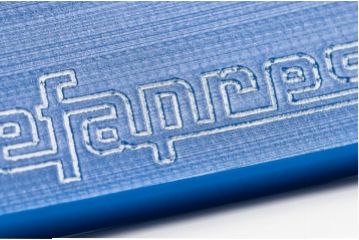

Marking types at Wefapress®: Quality you can see

At Wefapress® we attach great importance to ensuring that our products are clearly and unambiguously labeled. That is why we offer various types of marking tailored to the specific requirements of our products and customers. From needle embossing and hot stamping to milling and labeling – we ensure that our products are always marked correctly and professionally. In doing so, we always ensure compliance with all relevant standards and regulations.

- limited embossing choice

- colour choice: black, white

- unsuitable for direct food contact

- Costs: +++

- removable

- Dimension 54 x 101 mm

- Cost: +

- Text & logo embossing

- Implementation via CNC

- Marking range almost without limits

- Costs: ++

- Text & logo embossing

- Marking area 100 x 100 mm possible

- Costs: +

- Text & logo embossing

- colour choice: black, white

- not suitable for direct food contact

- Costs: +++

Our quality promise:

“Uncompromising focus on customer needs with a strong focus on sustainability.”

Quality standards you can count on

Even though we are not currently certified according to DIN ISO 9001, we align our processes and standards accordingly. This ensures that our products and services always meet the highest requirements.

Employees: the heart of our quality management

Every single employee at Wefapress is an integral part of our quality management. Their expertise and commitment are key to our outstanding quality.

Continuous improvement: our daily endeavor

Through our continuous improvement process (CIP), we ensure that we constantly develop and optimize our products and services.

Customer feedback: Our guide

Your feedback is important to us. It is an essential part of our CIP and helps us to continuously improve our products and services.

How we work

Our 5 steps to the best quality

Order control

Each order is carefully reviewed to ensure it meets our standards.

Incoming goods inspection

We inspect every shipment to ensure that it meets our quality requirements.

Production control

During the production process we carry out regular checks to ensure the highest quality.

Outgoing goods inspection

Before a product leaves our premises, it undergoes a final quality control.

Post calculation

We analyze and evaluate each process step to ensure continuous improvement.