Paper industry

High-quality plastic parts for the paper industry

At Wefapress, we are proud to have worked within the paper industry for many decades. Our years of experience and implementation of practical applications have enables us to develop high quality products that are bespoke to the paper industry. We create everything, from the highly resistant sheets, milled covers (that can have drilled or slotted perforation patterns) as well as fully finished parts. We guarantee first class quality at every juncture.

Our products are manufactured homogeneously from premium, ultra-high-molecular-weight polyethylene (PE-UHMW), for this application, we only use our virgin material. By using lubricants and specialist additives we have achieved the optimal qualities specifically for this material application, specifically extreme wear-resistance. Thanks to the press-sintering process that we use, we can ensure a stress-free internal structure which eliminates bowing. We can also produce semi-finished parts that can be further worked with a length of up to 10 meters without any weld seams.

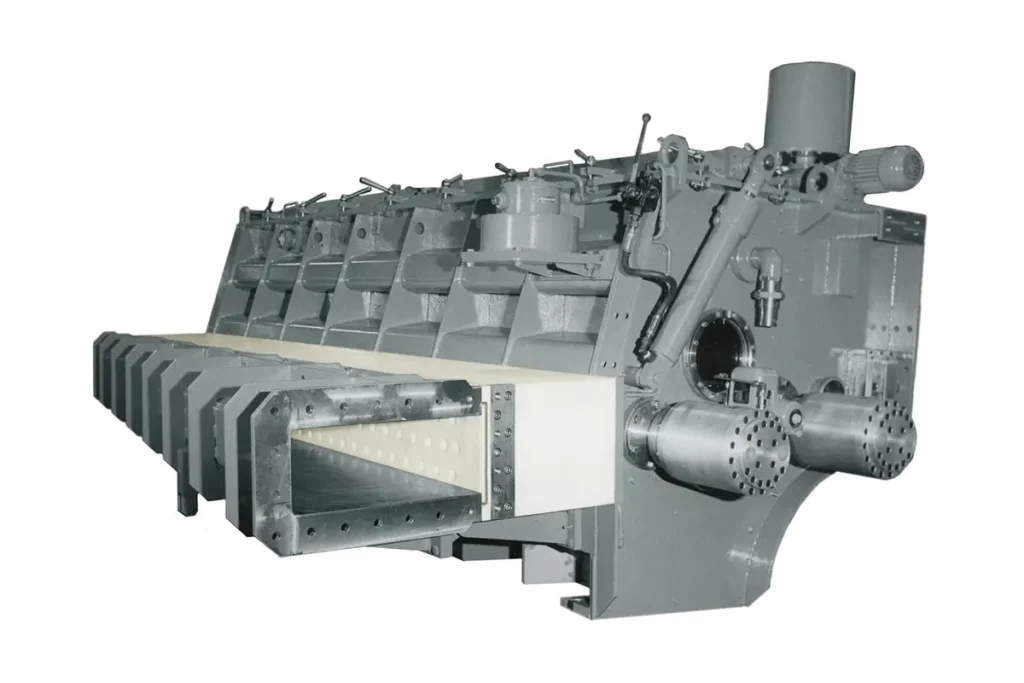

Diffuser block

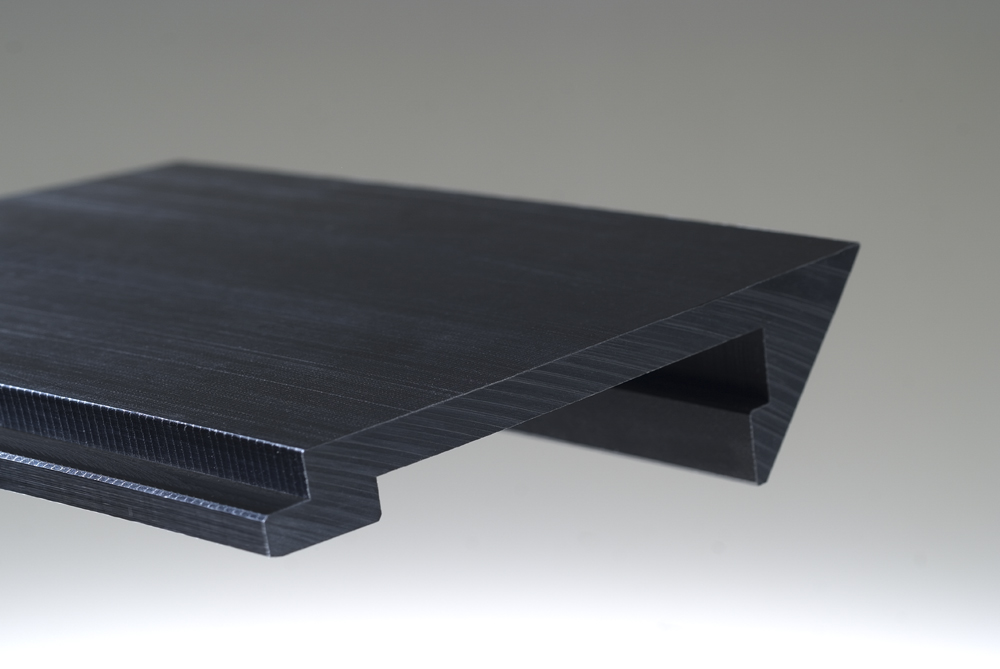

Drainage elements

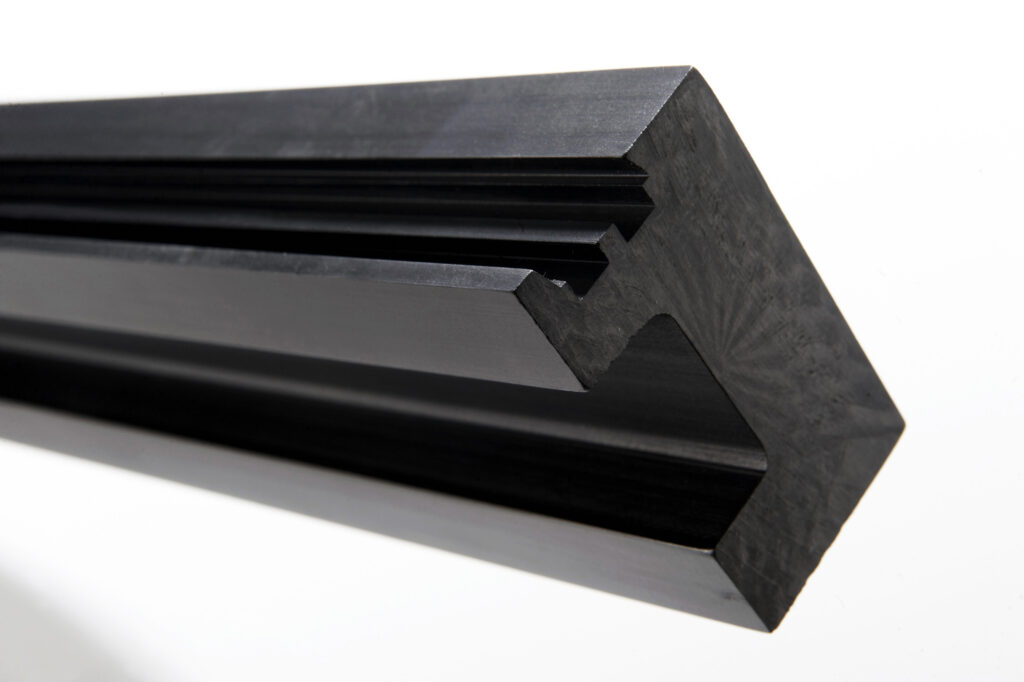

Doctor blades and water scraper blades

Sealing strips for suction rolls

Radial header

Gear wheels for drying cylinder drives

Our gears for drying cylinder drives are specially designed for the highly demanding application in drying hoods of the paper machines. They offer a durable and reliable solution for optimising the drive process and helps to reduce maintenance costs. The gears are made of high-strength plastic and ensure precise power transmission with minimum wear.

Format limiters and forming fabric edge lifters

Rod beds for coating units

Jaw coupling spiders for tambour drives

Tambour storage lining

Screw hutch linings for screw conveyors

Overview:

Why is plastic an advantage in the paper industry?

Plastic parts offer numerous advantages in the paper industry compared to traditional materials such as metal or wood. Their superior corrosion resistance guarantees a longer service life, even in humid or chemically aggressive environments, which are commonplace in the paper industry. In addition, the lower density of plastic ensures lighter components, resulting in reduced energy costs during machine operation.

The easy shaping properties of plastic enables the production of complex shapes and profiles that are tailor-made for specific applications in paper production. This means that plastic parts for the paper industry are often more precise and efficient than their counterparts made from other materials. In addition, the flexibility in the production of plastic parts allows them to be quickly adapted to new or changing production requirements without costly and time-consuming modification measures.

Because many plastics are inherently low-friction, both the plastic parts themselves and the machine elements that come into contact with them are subject to less wear and tear. This results in lower maintenance costs and smoother operation. With their ability to dampen vibrations and noise, plastic components contribute to a more pleasant working environment and more stable machine operation, which in turn increases product quality.

The adaptability of plastic parts to the demanding conditions of the paper industry makes them an optimal choice for manufacturers looking for sustainable, cost-effective and high-performance solutions. With the added benefit that plastics are easy to clean and maintain, operational hygiene is improved, which is particularly crucial in the production of food packaging or medical packaging materials.

Sustainability and efficiency through innovative plastic solutions

The use of plastic parts in the paper industry brings considerable ecological and economic benefits.

Due to their durability and recyclability, plastic components are a sustainable choice for the paper industry, helping to reduce operational costs and enhance production efficiency.

Plastic materials for the paper industry

Fields of application for plastic parts in the paper industry

- Diffuser block

- Drainage elements

- Sealing strips for suction rolls

- Format delimiter

- Scraper blades

- Gears

- Profiles and guides

- Format limiters and forming fabric edge lifters

- Rotary distributor

- Components in the wet end of paper machines

- Rod beds

- Jaw coupling spiders for tambour drives

- Tambour storage lining

- Screw trough linings for screw conveyors

- Individual solutions

Why choose Wefapress for your plastic parts in the paper industry?

Our commitment to quality and customer satisfaction

Contact us to learn more about our products and how we can help you improve the efficiency and quality of your paper production.